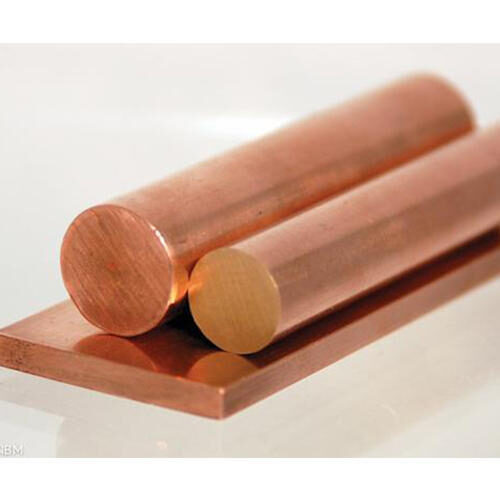

Specification of C18150 copper rod

|

Specification

|

ASTM C18150, UNS C18150

|

|

Standard & Material

|

CW106C, EN 12163 EN 12420 EN 1652, ASTM C18150, CC 102, CA 184

|

|

HOLLOW RODS

|

Min Bore Size 20 mm and Max OD 100 mm

|

|

ROUND RODS

|

8mm To 100 mm

|

|

HEX

|

10mm To 60mm

|

|

SQUARE

|

10mm To 60mm

|

|

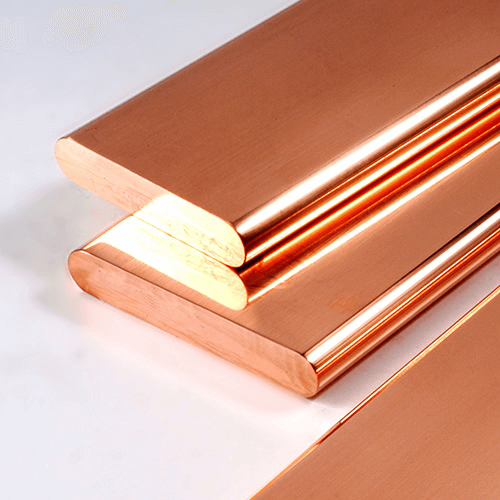

FLAT

|

10mm Min Thickness and max Width 120mm

|

|

BILLETS

|

Up to 200 mm

|

|

INGOTS

|

As per Specification

|

UNS C18000 Copper Chromium Nickel rod, C18000 Copper Chromium Nickel rod, Copper Nickel Silicon rod Suppliers.

Mechanical & Physical Properties of C18150 copper rod

| Mechanical specification | |||||

|

EN 12163

CW106C |

Round bar

|

Ts

N/mm² |

Ys

N/mm² |

A

% |

|

|

Temper 5470

|

∅ 6 to 25 mm

|

≥ 470

|

(380)

|

> 8

|

|

|

Temper 5440

|

∅ 26 to 50 mm

|

≥ 440

|

(350)

|

> 10

|

|

|

Temper R220

|

∅ 51 to 250 mm

|

≥ 200

|

(60)

|

> 30

|

|

|

Hexagonal bar

|

|||||

|

Temper R440

|

12 to 36

|

≥ 440

|

(350)

|

> 10

|

|

|

Square bar

|

|||||

|

Temper R420

|

10×10 to 50×50

|

≥ 420

|

(330)

|

> 12

|

|

|

DIN 17666 – 2.1580

|

Sheet

|

||||

|

Temper F37

|

Ep. 10 to 120 mm

|

≥ 370

|

> 270

|

> 12

|

|

Chemical Composition of C18150 copper rod

| Chemical composition | ||||||

| Cu | Cr | Zr | Fe | Si | Other | |

| EN 12163 – CW106C | Remainder | 0.5/1.2 | 0.03/0.3 | < 0.08 | < 0.1 | < 0.2 |

| DIN 17666 – 2.1580 | Remainder | 0.3/1.2 | 0.03/0.3 | < 0.2 | ||

Applications of C18150 copper rod

-

- Mold Cavities for Bold Molds

- Cores, Core and Ejector Pins for Injection Molds

- Plunger Tips for Metal Die Casting Machines

- Heat Sink Inserts in Steel Plastic Molds

- Hot runner Systems for Injection Molds

- Welding Dies for Wire and Flash

- Blow Pins

- Pinch Offs

- Mold Cavities for Bold Molds

- Blow Pins

- Resistance Welding Tips, Wheels and Fixtures

- Stud Welding Collets and Tips

- Sprue Bushing

- Cavities for Injection Molds

- Pinch Offs