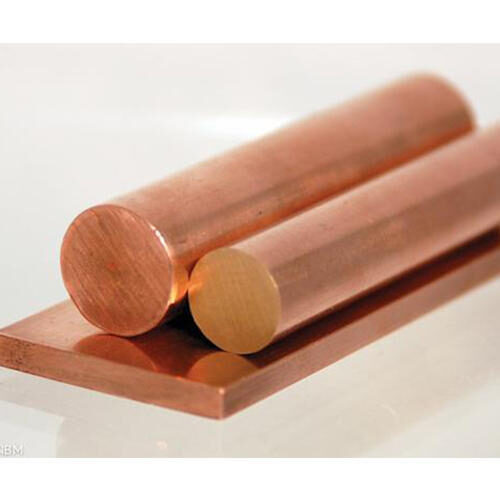

Specification of C18200 Copper Rod

|

End Product

|

Specification

|

|

UNS

|

UNS C18200

|

|

Bar

|

MILITARY MIL-C-19311

|

|

Forgins

|

MILITARY MIL-C-19311

|

|

Rod

|

MILITARY MIL-C-19311

|

C18200 Chromium Copper, UNS C18200 Chromium Copper, C18200 Chromium Copper Suppliers.

Sizes Available of C18200 Copper Rod

|

HOLLOW RODS

|

Min Bore Size 20 mm and Max OD 100 mm

|

|

ROUND RODS

|

8mm To 100 mm

|

|

HEX

|

10mm To 60mm

|

|

SQUARE

|

10mm To 60mm

|

|

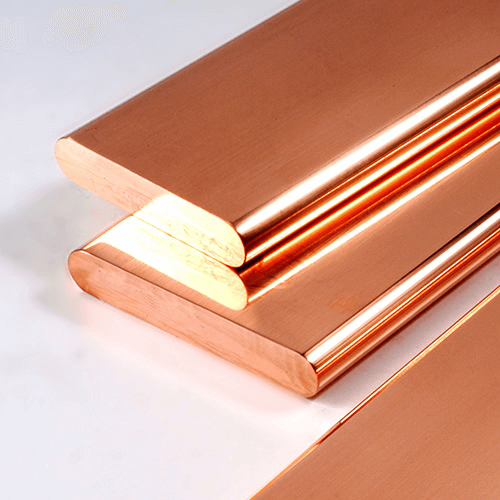

FLAT

|

10mm Min Thickness and max Width 120mm

|

|

BILLETS

|

Up to 200 mm

|

|

INGOTS

|

As per Specification

|

Chemical Composition of C18200 Copper Rod

|

Chemical composition

|

||||||

|

Copper (incl. silver)

|

Iron

|

Chromium

|

Silicon

|

Lead

|

||

|

99.1 Nominal

|

.10 Maximum

|

.60 Minimum

|

.10 Maximum

|

.05 Maximum

|

||

Applications of C18200 Copper Rod

- Electrical Applications : Switch Contacts, Electric Motor and Generator Components, Contacts, Wire, High Temperature, Semi Conductor Bases, Parts for Electronic Devices, Cable, Connectors, Thermal Conductors Requiring Greater Strength than Copper, Switch Gears, Electrical Connectors, Electrical Conductors Requiring Greater Strength than Copper, Arcing and Bridging Parts, Circuit Breaker Parts, Electron Tube Grid Side Rods

- Consumer Applications : Pencil-type & Light Soldering Guns: Tips, Rod Extensions

- Industrial Applications : Seam Welding Wheels, Electrode Holder Jaws, Flash Welding Electrodes, Plastic Mold Components, Resistance Welding Machine Electrodes, Flash Welding Electrodes, Current Carrying Shafts and Arms, Wear Plates on Heavy Equipment, Heat Sinks, Structural Parts, Spot Welding Tips, Molds

Mechanical Properties of C18200 Copper Rod

| Mechanical Properties | |||||

| Hardness* | Rockwell B Scales | 70 | |||

| Tensile Strength** | KSI | 70 | |||

| Yield Strength** | KSI | 55 | |||

| Elongation** | % in 2 inch | 21 | |||

Physical Properties of C18200 Copper Rod

|

Product Property

|

US Customary

|

Metric

|

|

Coefficient of Thermal Expansion

|

9.8 · 10 6? per °F (68-212 F)

|

17.6 · 10 6? per °C (20-300 C)

|

|

Density

|

0.321 lb/in3 @ 68 F

|

8.89 gm/cm3 @ 20 C

|

|

Electrical Conductivity

|

80 %IACS @ 68 F

|

0.468 MegaSiemens/cm @ 20 C

|

|

Electrical Resistivity

|

13.0 ohms-cmil/ft @ 68 F

|

2.16 microhm-cm @ 20 C

|

|

Melting Point Liquid US

|

1967 F

|

1075 C

|

|

Melting Point Solid US

|

1958 F

|

1070 C

|

|

Modulas of Elasticity in Tension

|

17000 ksi

|

117000 MPa

|

|

Modulas of Rigidity

|

7200 ksi

|

49640 MPa

|

|

Specific Gravity

|

8.89

|

8.89

|

|

Specific Heat Capacity

|

0.092 Btu/lb/°F @ 68 F

|

385.5 J/kg · °K at 293 K

|

|

Thermal Conductivity

|

187.0 Btu · ft/(hr · ft2 ·°F) @ 68 F

|

323.6 W/m · °K at 20 C

|

Fabrication of C18200 Copper Rod

|

Joining Technique

|

Suitability

|

|

Brazing

|

Good

|

|

Butt Weld

|

Fair

|

|

Capacity for Being Cold Worked

|

Excellent

|

|

Capacity for Being Hot Formed

|

Good

|

|

Coated Metal Arc Welding

|

Not Recommended

|

|

Forgeability Rating

|

80

|

|

Gas Sheilded Arc Welding

|

Good

|

|

Machinability rating

|

20

|

|

Oxyacetylene Welding

|

Not Recommended

|

|

Seam Weld

|

Not Recommended

|

|

Soldering

|

Good

|

|

Spot Weld

|

Not Recommended

|